An introduction to

Coffee Roasting

Coffee roasting is a fascinating combination of art and science. At once simple—put green coffee beans in a hot rotating drum until they turn brown—and a complex synthesis of chemical reactions, coffee roasting is the core of everything we do here at Glen Lyon Coffee Roasters (that’s why it’s in the name).

For those interested in learning more about this fascinating subject, we’ve put together a guide to help you understand how your coffee goes from green to that fragrant brown bean that we all so love.

WHAT IS COFFEE ROASTING?

At its very simplest level, coffee roasting is the act of applying heat to green coffee beans in order to change their chemical structure and release the volatile compounds that, once ground and brewed, make the delicious beverage we all know and love.

At a commercial scale, most coffee is roasted using drum roasters which are heated in various ways depending on the manufacturer and style. At Glen Lyon Coffee we roast on two beautiful Probat P series machines manufactured in Germany, which combine the classic craft of traditional drum roasting with modern, state-of-the-art German engineering.

THE COFFEE ROASTING PROCESS

After coffee has been processed it is shipped to our roastery in Aberfeldy. It is stored in jute or hessian sacks, often with a ‘Grainpro’ liner inside to protect the beans from staling, until it is ready to roast. Processed green coffee contains between 7-12% water by weight, depending on the method used, and most of that water needs to be roasted out of the final coffee.

The green coffee is weighed out and lifted into the green chute, a cone-shaped receptacle at the top of the roaster, where it awaits its fate. Once the roaster reaches the desired temperature (around 200°C) the coffee is dropped from the chute into the rotating drum, where blade-like mixers spin it around within the drum.

This first stage of the process is endothermic, as the beans absorb heat from the drum and begin to dry out. After this the beans start to brown due to the Maillard reaction (the same process that turns toast brown) and caramelisation and the coffee heads for the crucial stage known as first crack.

The increasing internal temperature and a build-up of gases such as carbon dioxide cause first crack, which refers to the popping sound the beans make as the water within them evaporates and gas escapes, and it indicates that the roast is nearly complete. At this point the process becomes exothermic, as the beans release built-up energy, steam, and carbon dioxide, and expand in size.

The time after first crack is most critical of all, as the longer the coffee is roasted after this point the more developed and darker it will become. Every company has its own roasting style, and the length and final temperature of the roast plays a big part in that. Generally speaking, lower quality coffee tends to be roasted darker to hide its imperfections.

THE SCIENCE BEHIND COFFEE ROASTING

Let’s take a closer look at some of the reactions going on inside the drum:

Maillard Reaction: this is a non-enzymatic browning reaction that occurs when simple sugars and amino acids interact, usually requiring the presence of heat. When your bread turns to toast, or your marshmallow browns over a fire, that’s Maillard. In coffee this reaction happens before first crack and creates hundreds of flavour and aromatic compounds.

Caramelisation: similar to the Maillard reaction, caramelisation is another non-enzymatic browning reaction that involves the browning of simple and complex sugars. This again takes place under the influence of heat and results in the release of aromatic and acidic compounds.

First crack: this is when water within the bean vaporises and forces its way out along with carbon dioxide and other compounds, causing a lovely rolling popping sound similar to popcorn in a hot pan. At this point the beans also lose some density while becoming more porous and brittle. Between first and second crack the bean once again absorbs heat, and the pressure within begins to increase.

Second crack: As the coffee roasts further and the temperature increases, a second audible popping or snapping sound means that the coffee has reached second crack. This is where carbon dioxide and other gases build up and the cell walls of the coffee can’t cope and start to break down, allowing the gases to escape in another exothermic reaction. Past this point the coffee will become very dark and exhibit “roasty” flavours, along the lines of burnt toast. If you’ve ever seen shiny, almost black coffee beans in a store or cafe, they’ve most likely been roasted past second crack.

OUR APPROACH TO COFFEE ROASTING

It’s become a cliche for roasters to say that “we roast to bring out the best from every coffee”, but some cliches are true: the best way to approach a coffee is individually.

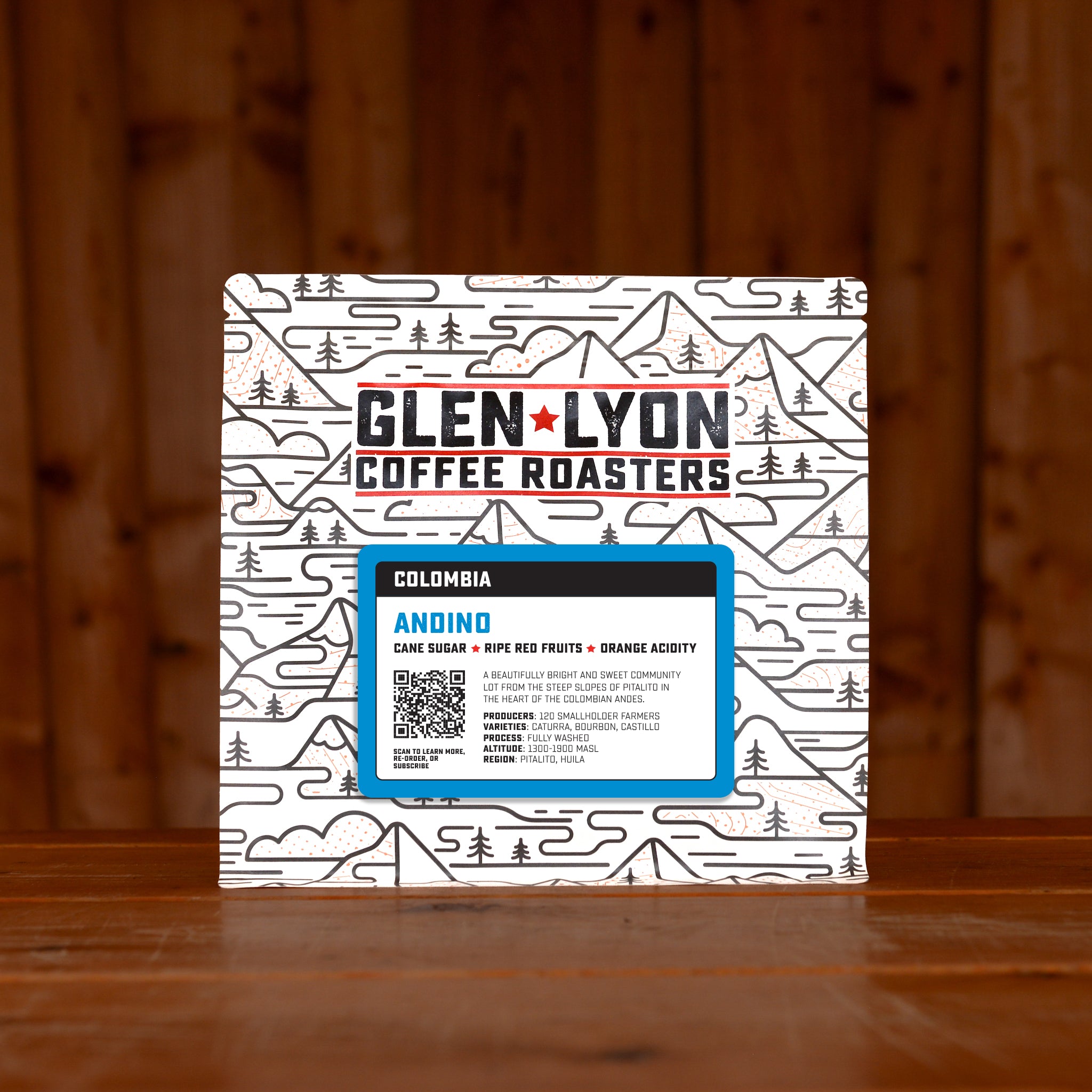

All coffees are unique, even if they come from the same country, municipality, or even the same farm—two different lots from the same producer might roast completely differently, depending on the variety or the growing conditions, or how they were processed. Two harvests of the exact same coffee can even act differently. It is one of the challenges—and great pleasures—of working with an agricultural product.

That being said, at Glen Lyon Coffee Roasters we have a few principles that we apply to all the coffees that come through our roastery’s roller door:

Every coffee is profiled by our head of coffee and certified Q Grader Fiona Grant, to ensure that it matches with her vision of a ‘Glen Lyon’ coffee.

While we don’t roast “Scandinavian-light”, we also don’t push our coffees into second crack. For us, the perfect development is a little past first crack, allowing the inherent sweetness and character of each coffee to come to the fore but before those “roasty” flavours start to form.

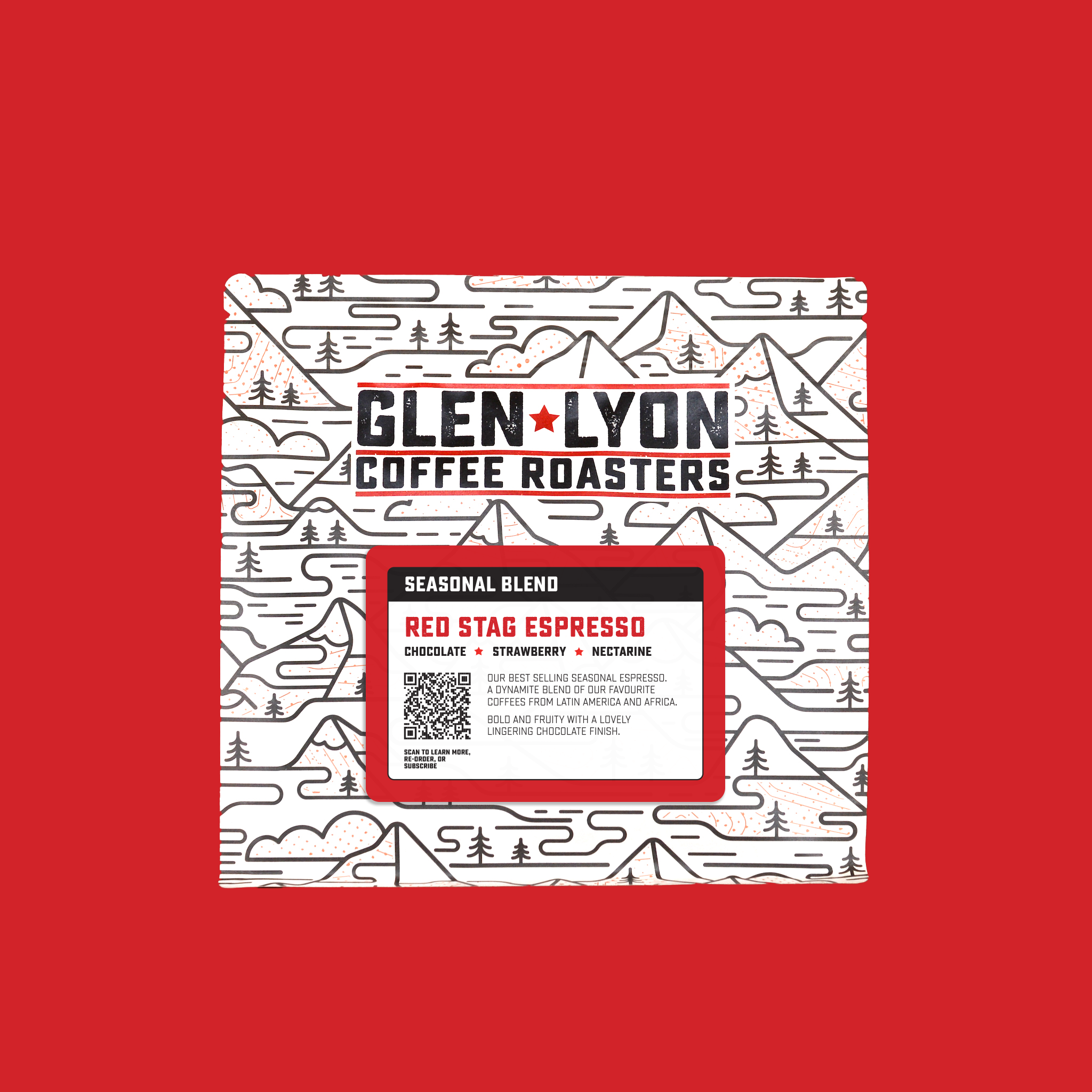

For us, roasting for single origin and for espresso requires two different approaches—our Red Stag Espresso is a little more developed to enable easy and consistent extraction.

We roast to order, so that every coffee we send out is as fresh as possible (whether you’d like to rest your coffee once you receive it is up to you).